IACOMELLI - STEEL ENGINEERING

company profile

Work ethics and respect for the customer mean that we give firm delivery times and previde clear and adequate prices.

lt is the skilled hands of our welders that make the difference in our steel products

AII our production, from the large hatch to the small handle, is made in ltaly. Safety, quality, and the ability to keep a business alive in the piace where it was bom are our creed, enclosed in these 3 simple words.

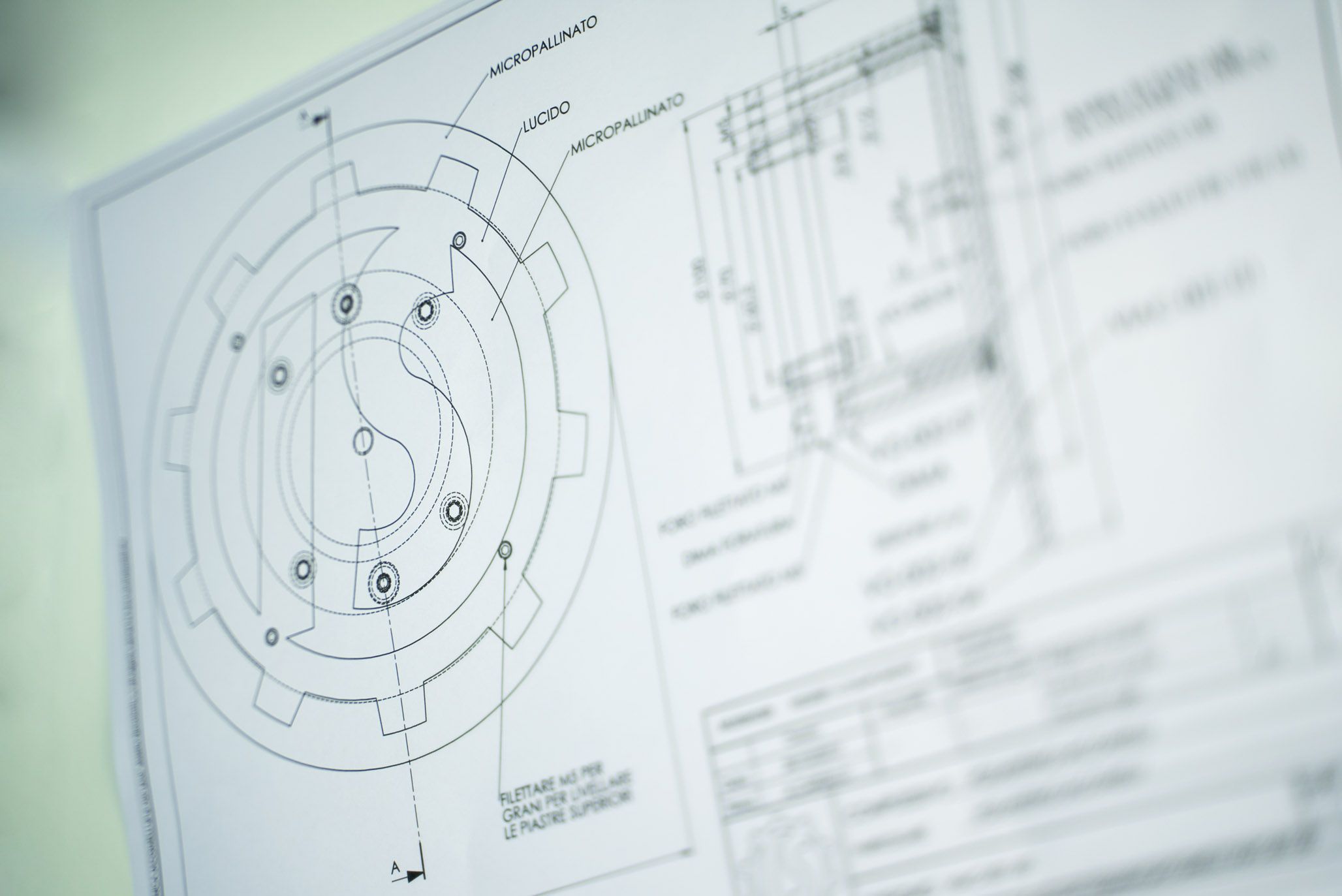

Our engineers develop customer ideas and support them step by step unti! the product is delivered.

Work ethics and respect for the customer mean that we give firm delivery times and previde clear and adequate prices.

OUR VISION

“We believe that our first responsibility is to the customer who uses our products.

It is the daily attention of our team that makes our stainless steel and aluminium components functional, elegant, capable of satisfying specific client requirements.

Our ability of maintaining all aspects of production in Italy enables us to meticulously control the entire development process.”

SHIPBUILDING

Since 1975 IACOMELLI has been a partner to naval shipyards both in Italy and abroad, with the manufacturing of hatches, doors, vents, components, and accessories for yachts.

Exquisite metal carpentry for the shipbuilding industry is the result of the expertise of engineers, technicians, and welders.

The transformation of stainless steel and aluminium sheets into products are the hallmarks of our work.

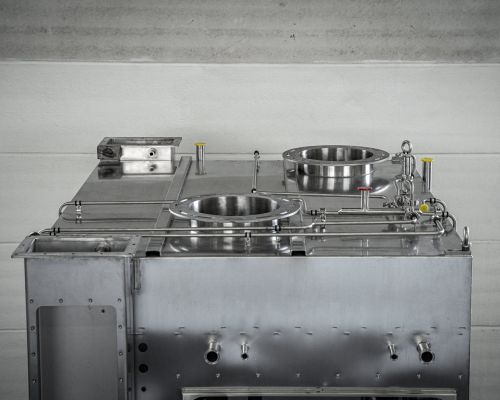

PHARMA

"Metal carpentry for the pharmaceutical industry is an activity that requires highly skilled work.

Stainless steel processing is the first step in obtaining products suitable for the pharmaceutical industry, given the high standards needed for the final product.

All our production is based on the design of the customer, for this reason all our products are customized and personalized.

From cutting to bending, from welding to polishing, and finishing with assembly, it is the capabilities of our welders that make our products different from our competitors.

Among the pharmaceutical carpentry elements, we can manufacture:

- Frames

- Drum heating cabinets

- Isolators

- Pipes

- Mixers

- White rooms, bins and components for the pharmaceutical production line.

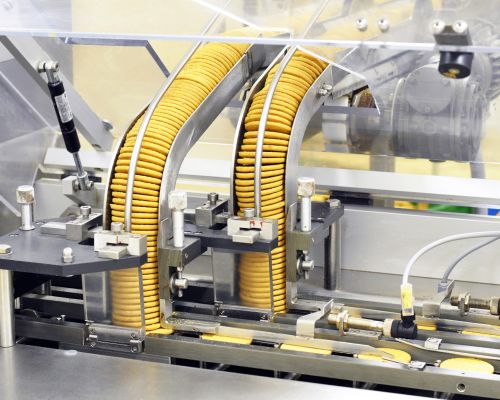

FOOD

Metal carpentry for the food industry is an activity that we established thanks to the high-level expertise of our staff of engineers, welders, and skilled workers.

Starting from the technical design, going from laser cutting, to folding, to welding entrusted to skilled hands, stainless steel is processed and moulded and polished to create new structures that will become special, completely customized, and unique machinery.

The stainless-steel production for the food industry ranges in many types of machinery and components, constantly updated:

Frames - stairs - washing-rows - masks - metal structures shelves - tanks - scrap collection - flooring - pliers - trolleys - components for pasta machinery.

ARCHITECTURE

Working with stainless steel allows you to enter many areas and venture into the creation of carpentry for the architectural sector, giving character and personality to various settings.

At IACOMELLI we love to collaborate with architects and artists to help them transform and idea into a concrete product

CONTACTS